Medio ambiente

We are working towards long-term sustainability: we will operate safely and responsibly and aim to minimise our impact on the environment.

Everyone at Perfetti Van Melle understands that sustainability is both an individual and collective responsibility.

Everyone at Perfetti Van Melle understands that sustainability is both an individual and collective responsibility.

All our operating companies have set targets and have developed programmes and activities to make progress in environmental care. Some of our companies already produce a Corporate Responsibility report highlighting results and goals for the future, others will follow soon.

We are mainly focused on:

- Reducing the energy, gas and water we use in our manufacturing processes

- Reducing waste from manufacturing – some of our units have embraced the challenging goal of Zero Waste to Landfill

- Adopting renewable energy sources when possible

- Reducing packaging material

- Obtaining ISO 14001 certification to set up an environmental management system in our units

- Reducing our C02 footprint

Energy savings at Lainate

At our Lainate factory we have obtained energy savings of over 231,000 Kwh by replacing many of the lamps used in the production spaces with low energy consumption lamps. Replacements will continue in 2014 to achieve further savings of 77,000 Kwh.

At our Lainate factory we have obtained energy savings of over 231,000 Kwh by replacing many of the lamps used in the production spaces with low energy consumption lamps. Replacements will continue in 2014 to achieve further savings of 77,000 Kwh.

In the last two years, we reduced by about 23% the weight of our plastic (PE Polyethylene, 100% recyclable) 150 ml chewing gum bottles, from 26g to 20g.

The Lainate factory achieved the ISO 14001 certification in February 2013

The canteen at the Lainate factory was restructured in an environmentally friendly style (recyclable plastic furniture, energy efficient window panes etc) in early 2014.

The canteen at the Lainate factory was restructured in an environmentally friendly style (recyclable plastic furniture, energy efficient window panes etc) in early 2014.

Managing waste water

At our factories in Shanghai and Shenzhen, two sets of on-site waste water treatment systems are capable of processing 500m3 and 750m3 of waste water on a daily basis. All waste water generated and discharged during our production and operation activities is effectively processed and efficiently recycled.

In Shanghai, we collect the biogas produced during the waste water treatment process and use it as fuel for production, further reducing our consumption of natural resources.

Savings through efficiencies

PVM China endeavours to reduce its consumption of natural resources and actively improve performance by replacing high maintenance facilities with advanced highly efficient equipment. This approach achieved an annual reduction of water, gas and power consumption per unit production output by 3-5% since 2011.

Saving fuel

At our Bogor plant we have installed economisers on our boilers to recover the heat. This has resulted in shutting down one of the heat exchangers supplying the vapour absorption chiller. The saving in fuel (LNG) due to this is 153,000 cu. meter per year.

Auditing our steam distribution systems

We have conducted a steam distribution system audit in association with Spirax Sarco. By following the audit’s recommendations we were able to improve the efficiency of our recovery system, resulting in a saving of 700tons of steam per year from both our plants, Bogor and Purwakarta.

Saving electricity

We’ve replaced the electric heaters used for jacketing of tanks and pipelines with hot water returned from our air handling system. This has resulted in an electricity saving of 475,000KWH per year.

Saving natural gas

In Breda in 2013 we managed to save 31,500-m3 of natural gas with our solar panels. With this much natural gas you can heat 21 family homes. We also recover used heat with technical applications such as condensate buffers, compressed air installations and a flue gas condenser for the steam boiler. With the amount of heat we recovered, 339 family homes can be heated. In addition, Breda has lowered the steam pressure, both during production as in the weekend. This resulted in a saving of over 200,000 m3 in 2013. The cooling machines are being shut down at the weekend when the outside temperature is below 12 degrees Celsius. This is called free cooling and resulted in a saving of 200,000 kWh in 2013.

Raising awareness of saving water

At our factory in Mexico we have obtained water savings of 137,642 litres by setting chiffons in the hoses and carrying out – and following up – an internal awareness campaign. Our objective was to optimise the water consumption and achieve a 5% reduction; this target was slightly exceeded. The goal for 2014 is to achieve further savings of 2.4% of water consumption.

Building a better world

We launched a reforestation campaign in 2011, planting 200 trees every year, rising to 250 trees in 2013. The goal for 2014 is to plant another 250 trees and take care of those we have already planted. A plaque was placed at the park where we planted the trees with the message: “Earth is not inherited from our parents, it is borrowed from our children. Chupa Chups building a better world”.

Re-evaluating distribution

Our company in Spain, Chupa Chups SAU, ships millions of lollipops to various countries in the world, with Japan the most distant destination. In 2010, we carried out a study, in association with Barcelona Port Authorities, to calculate the CO2 emissions originated by our export to Japan and to evaluate possible strategies for reducing these impacts.

Our company in Spain, Chupa Chups SAU, ships millions of lollipops to various countries in the world, with Japan the most distant destination. In 2010, we carried out a study, in association with Barcelona Port Authorities, to calculate the CO2 emissions originated by our export to Japan and to evaluate possible strategies for reducing these impacts.

After the study, we implemented a plan to re-route part of the traffic and minimise land transport, resulting in a 12% reduction in CO2 emissions in the first year and a further 6% reduction the following year. That makes an 18% reduction overall of the 383 tons of CO2 emissions we measured in 2010.

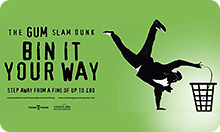

Enjoying chewing gum responsibly

Dropped chewing gum is litter that can’t simply be swept away. Perfetti Van Melle UK is part of The Chewing Gum Action Group which runs a campaign which unites the manufacturers, Government and the charity, Keep Britain Tidy, to encourage people to enjoy chewing gum, but to dispose of it properly. 2014’s ‘Bin it your way’ campaign is scheduled for September. For more information, please visit:

Dropped chewing gum is litter that can’t simply be swept away. Perfetti Van Melle UK is part of The Chewing Gum Action Group which runs a campaign which unites the manufacturers, Government and the charity, Keep Britain Tidy, to encourage people to enjoy chewing gum, but to dispose of it properly. 2014’s ‘Bin it your way’ campaign is scheduled for September. For more information, please visit:

Alternative energy

In Erlanger we implement systems to produce alternative energy and therefore reduce the amount of natural resource consumption. These systems make use of both photovoltaic (PV) cells and solar hot water panels.

In Erlanger we implement systems to produce alternative energy and therefore reduce the amount of natural resource consumption. These systems make use of both photovoltaic (PV) cells and solar hot water panels.

All offices and conference rooms make use of motion sensor lighting. Furthermore, specially designed skylights have been installed which maximize the amount of natural light entering into the building. This results in less use of electricity for artificial lighting. We also make use of a heating and cooling geothermal system.